Flow Assurance Studies Detail

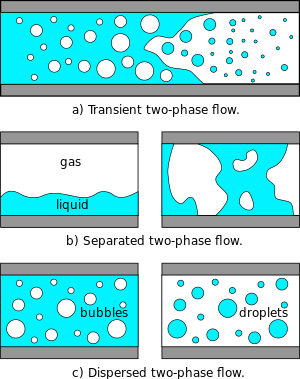

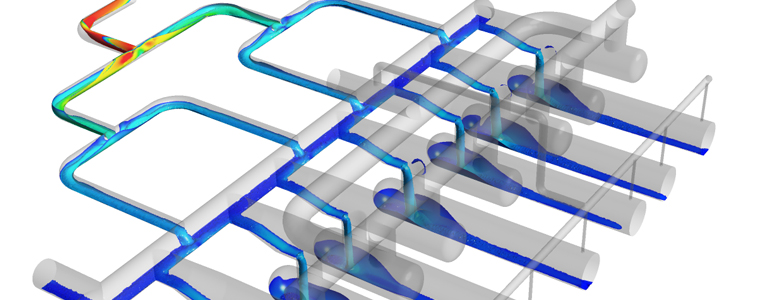

Flow assurance, also known as multiphase transport, involves the transport of a mixture of oil, gas, condensates and water in the same pipeline. It's an area in which we have extensive experience.

We have Experienced Team who can perform Flow Assurance analysis to ensure proper design of your pipelines and downstream Slug catchers and liquid handling system.

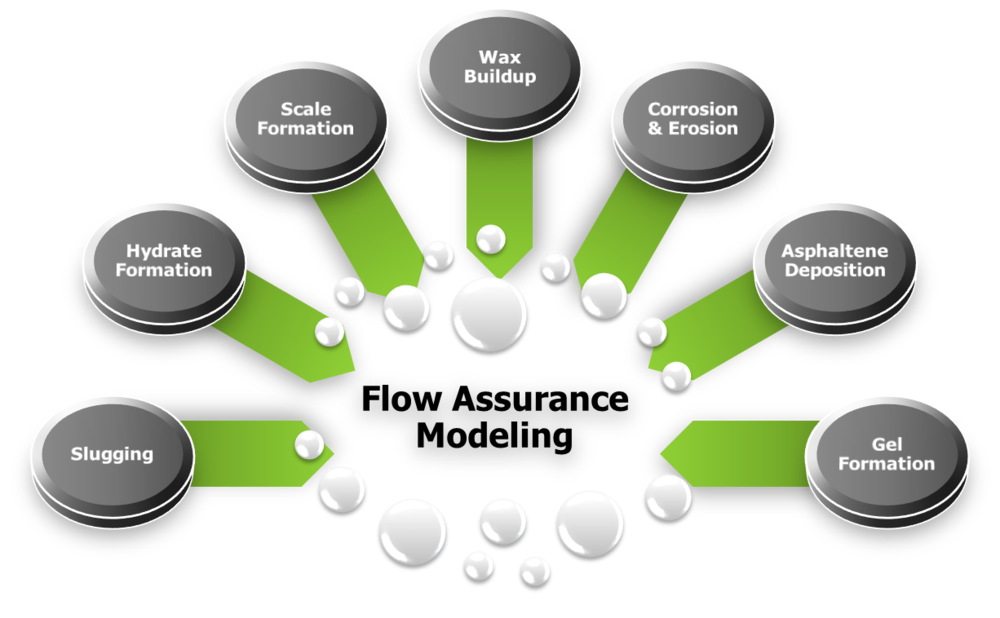

Key flow assurance activities we support are:

| 1. Steady State and Transient Multiphase modeling of single pipelines/networks |

| 2. Detailed Well Modeling (Start-up, Shutdown, Well stability) |

| 3. Liquid Management in a Multi-phase Pipeline Network (Slugging, Slug-catcher Sizing, Pigging) |

| 4. Modeling of Pipeline Thermal Behavior (Insulation, Active Heating) |

| 5. Solids Management ( Wax, Asphaltene, Hydrates, Sand) |

| 6. Corrosion/Erosion Analysis |

| 7. Overpressure Protection Studies – Line pack , Water Hammer |

| 8. Pre-Commissioning Commissioning studies (Pipeline Comm, Well Offloading) |

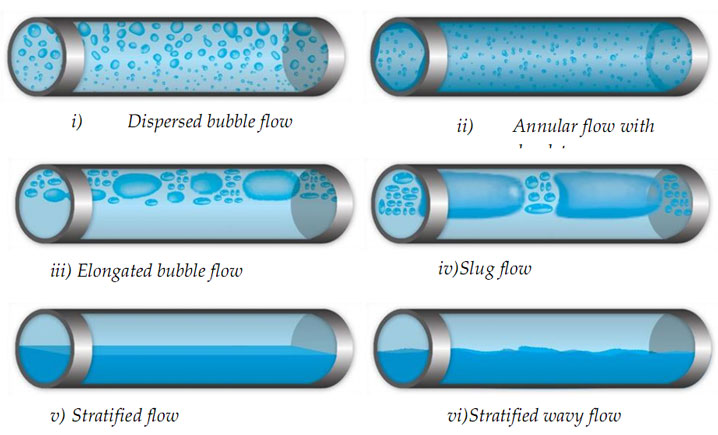

Slugging is a major flow assurance challenge. It refers to varying or irregular flows of gas and liquids (or liquid surges) in pipelines.

These can take several forms, with 'riser slugging' as one of the most serious in systems dominated by oil/water flows.

In such cases, liquid blocks the low point where a down-sloping pipeline is attached to a riser carrying the wellstream up to the platform.

Such blockages initiate the slug, which grows upward in the riser and back through the pipeline.

Once enough gas pressure has built up behind the slug, the latter is blown out of the riser. The entire cycle is then repeated.

In this way, riser slugging can affect the regularity of the receiving facilities – particularly the first-stage separators which remove gas from the oil and water.

The separator control valves are simply unable to react fast enough to deal with the rapid changes in liquid level.

Making allowances for intermittent storage of extra liquid in the inlet separators is the commonest way of handling heavy slugs on processing platforms.

A better alternative is to use static choking at the point where risers enter the processing facilities, by increasing the pressure drop across slugs.

This forces slugs back down a riser until a more stable, bubbly gas/liquid flow is established. But it also reduces the rate of production.

An answer to this has been to develop the innovative concept of active slug control, where continuous flow and pressure measurements are used to adjust the opening of a topside choke automatically to keep slugging in check.

Introducing faster control systems makes it possible to achieve a relatively constant flow through the topside choke. This increases stability and is adaptable to slowly changing production rates.

Flow Assurance - Diagram 1

Flow Assurance - Diagram 2

Flow Assurance - Diagram 3

Flow Assurance - Diagram 4